agilus30 tear test|agilus 30 material data sheet : manufacturing Agilus30 is a PolyJet Photopolymer with superior tear-resistance, capable of withstanding repeated flexing and bending. The ideal material for rapid prototyping and design validation, . Slender: The Arrival > Guides > Boop's Guides This item has been removed from the community because it violates Steam Community & Content Guidelines. It is only visible .

{plog:ftitle_list}

Resultado da Apenas com alguns banners de gifs que promoviam outros sites de parceiros, e era isso. Era só isso! O Sotemnovinhas.com foi uma lufada de ar fresco, já que sua seleção de vídeos, para minha surpresa, é muito diferente do que esperarias de um site com canal de vídeos gratuitos em português.

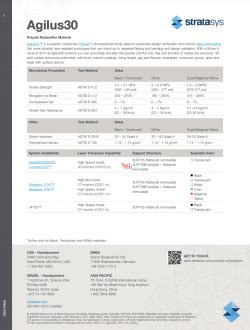

Agilus30™ is a superior rubberlike PolyJet™ photopolymer family ideal for advanced design verification and rapid prototyping. Get more durable, tear-resistant prototypes that can stand up to repeated flexing and bending.Agilus30 is a PolyJet Photopolymer with superior tear-resistance, capable of withstanding repeated flexing and bending. The ideal material for rapid prototyping and design validation, .Agilus30TM is a superior Rubber-like PolyJetTM photopolymer family ideal for advanced design verification and rapid prototyping. Get more durable, tear-resistant prototypes that can stand .

Agilus30™ is a superior Rubber-like PolyJet™ photopolymer family ideal for advanced design verification and rapid prototyping. Get more durable, tear-resistant prototypes that can stand

Agilus30 is a superior rubber-like PolyJet photopolymer family ideal for advanced design verification and rapid prototyping. Get more durable, tear-resistant proto-types that can stand .Agilus30TM is a superior rubber-like PolyJetTM photopolymer family ideal for advanced design verification and colorful rapid prototyping. Get more durable, tear-resistant prototypes that can .

Agilus30 is an advanced PolyJet material designed to create flexible parts. The parts Agilus30 produces are flexible, yet strong parts making a wide range of colors and Shore A values possible with its three colors – clear, black and .

AGILUS30 (FLX 2040) AND AGILUS30 BLACK (FLX9840) MECHANICAL PROPERTIES TEST METHOD ENGLISH METRIC Color/ Appearance Visual Black & Translucent Black & Translucent Tensile Strength ASTM D412 348-450 psi 2.4-3.1 MPa Elongation @ Break ASTM D412 220-270% 220-270% Compressive Set ASTM D395 6-7% 6-7% Tensile Tear Resistance ASTM .Get more durable, tear-resistant prototypes that can stand up to repeated flexing and bending. With a Shore A value of 30 in clear, black and white, . Agilus30 Mechanical Properties Test Method Value Black / Translucent White Tensile Strength ASTM D-412 2.4 – 3.1 MPa (348 – 450 psi) 2.1-2.6 MPaGet more durable, tear-resistant prototypes that can stand up to repeated flexing and bending. With a Shore A value of 30 in clear, black and white, . Agilus30 Mechanical Properties Test Method Value Black / Translucent White Tensile Strength ASTM D-412 2.4 – 3.1 MPa (348 – 450 psi) 2.1-2.6 MPa

The Agilus30 collection of 3D printing materials allows product designers to accurately prototype, simulate and test designs across a range of sectors. From small components, such as rubberised linings or simulated plaque build-up to complete rubber-based products, Agilus30 is the ideal material for in-depth testing.Agilus30 is a PolyJet Photopolymer with superior tear-resistance, capable of withstanding repeated flexing and bending. The ideal flexible 3D printing material for rapid prototyping and design validation, this rubber-like material simulates .Get more durable, tear-resistant prototypes that can stand up to repeated flexing and bending. With a Shore A value of 30 in clear, black and white, . Agilus30. Mechanical Properties. Test Method. Value: Black / Translucent: White: Tensile Strength; ASTM D-412. 2.4 – 3.1 MPa (348 – 450 psi) 2.1-2.6 MPa (305 – 377 psi) Elongation at Break.

Blur Busters UFO Motion Tests with ghosting test, 30fps vs 60fps, 120hz vs 144hz vs 240hz, PWM test, motion blur test, judder test, benchmarks, and more.Agilus is a flexible, rubber-like resin with superior tear-resistance and elongation at break. It is ideal for concept models and rapid prototyping of rubber components like grips, seals, and non-slip surfaces, or other components that will be subject to repeated flexing and bending. It is durable and tear-resistant, allowing users to create realistic and flexible 3D prototypes. . These prototypes can be used to “test and verify any design that includes rubber,” including footwear, handles, gaskets, and grips. Agilus30 can also be combined with other materials for multi-material prototypes that require vibration .

Get more durable, tear-resistant prototypes that can stand up to repeated flexing and bending. With a Shore A value of 30 in clear, black and white, . Agilus30 Mechanical Properties Test Method Value Black / Translucent White Tensile Strength ASTM D-412 2.4 – 3.1 MPa (348 – 450 psi) 2.1-2.6 MPais outstandingly tear-resistant and can withstand repeated bending and twisting. It is suitable for the production of long-lived, highly flexible, high-precision pieces. Agilus 30 simulates the appearance, feel and function of rubber, and has a Shore A value of 30 in clear or black. It is ideally suited for design validation.

Agilus30™ is a superior Rubber-like PolyJet™ . verification and rapid prototyping. Get more durable, tear-resistant prototypes that can stand up to repeated flexing and bending. With a Shore A value of 30 in clear or black, Agilus30 accurately simulates . TEST METHOD: IMPERIAL METRIC: Tensile Strength: ASTM D-412: 348-450 psi 2.4-3.1 .Get more durable, tear-resistant prototypes that can stand up to repeated flexing and bending and design validation. With a Shore A . Agilus30 Mechanical Properties Test Method Value Black / Translucent White Cyan/Magenta/Yellow Tensile Strength ASTM D-412 2.4 – 3.1 MPa (348 – 450 psi) 2.1-2.6 MPaAgilus30™ is a superior Rubber-like PolyJet™ . verification and rapid prototyping. Get more durable, tear-resistant prototypes that can stand up to repeated flexing and bending. With a Shore A value of 30 in clear or black, Agilus30 accurately simulates . TEST METHOD IMPERIAL METRIC Tensile Strength ASTM D-412 348-450 psi 2.4-3.1 MPa .Get more durable, tear-resistant prototypes that can stand up to repeated flexing and bending and design validation. With a Shore A . Agilus30 Mechanical Properties Test Method Value Black / Translucent White Cyan/Magenta/Yellow Tensile Strength ASTM D-412 2.4 – 3.1 MPa (348 – 450 psi) 2.1-2.6 MPa

Agilus30 is an outstanding rubber-like PolyJet Photopolymer family ideal for advanced design verification. Offering superior durability, tear-resistance, and shape memory, this material accurately simulates the look, feel, and function of rubber-like products. Agilus30 has a Shore A value of 30 in both clear and black.To check your report status Call us at 91115 91115. × Close. Welcome to Agilus*NEED PRIOR APPOINTMENT FOR THIS TEST* Know More. Complete Care Premium Men ₹6499. Know More. Complete Care Diabetes & Heart Advance ₹3499. Know More. Complete Care Diabetes & Heart ₹1499. Know More. Complete Care Student Basic ₹2499. Know More. Complete Care Pre - Marriage ₹2999. Know More.

Agilus30; RGD450; VeroClear; Metal Alloys. Direct Metal Laser Sintering (DMLS) Aluminum AISi10Mg; Aluminum 6061; Stainless Steel 316L; Stainless Steel 17-4 PH; Maraging Steel; Titanium Ti64; . Mechanically, Agilus 30 stands out due to its high tear resistance and elongation at break, which can exceed 200% in some conditions. . The Stratasys Agilus30 rubber-like material family from Stratasys provides new levels of tear resistance, elongation at break and tensile strength, making it. Agilus30™ by Stratasys is a highly durable, superior rubber-like photopolymer grade. . Test Condition. Test Method. Tensile Strength. 2.4 - 3.1 MPa ASTM D412 . Compressive set. 6 - 7 % ASTM D395 . Tensile Tear Resistance. 5 - 7 Kg/cm ASTM D624 . READ MORE. Last edited March 18, 2021. Want to list or update your products? View the .

Product specifications subject to change without notice. MSS_PJ_Agilus30_0121b PolyJet Rubberlike Material Agilus30™ is a superior rubberlike . PolyJet™ photopolymer family ideal for advanced design verification and rapid prototyping. Get more durable, tear-resistant prototypes that can stand up to repeated flexing and bending.Comprehensive test offerings providing one stop solution for diagnostic requirements . We offer a comprehensive test menu across pathology and radiology segments, with over 3,600 tests, as of March 31, 2023, comprising routine and specialized tests and have performed over 300.00 million tests since 2008. Our test menu includes: (i) pathology .

Get more durable, tear-resistant prototypes that can stand up to repeated flexing and bending. With a Shore A value of 30 in clear, black and white, . Agilus30 Mechanical Properties Test Method Value Black / Translucent White Tensile Strength ASTM D-412 2.4 – 3.1 MPa (348 – 450 psi) 2.1-2.6 MPaWith over 28 years of experience, we offer a comprehensive test menu of 3,600+ tests, including blood tests and full body health checkups. Our network includes 400+ labs, 3,900+ customer touchpoints and 12,000+ direct clients across 1,000+ cities in 30 states and union territories, with 43 NABL/CAP accredited labs.Rubber-like Polyjet materials like TangoPlus and Agilus30, you can simulate rubber with varying levels of hardness, elongation and tear resistance. With colours such as grey, black, white, and translucent, Rubber-like material enables manufacturers to create realistic prototypes to test and verify any design that includes rubber.

agilus 30 material data sheet

agilus 30 material

8 de fev. de 2024 · ⭐️ Paper Review Pro. A GPT that evaluates academic papers with precision, offering scores, identifying weaknesses, and suggesting edits to enhance quality and innovation. Chat now; 💡 Auto Thesis PPT. A PowerPoint assistant that drafts outlines, enhances content, and styles slides for thesis, business reports, or project reports with .

agilus30 tear test|agilus 30 material data sheet